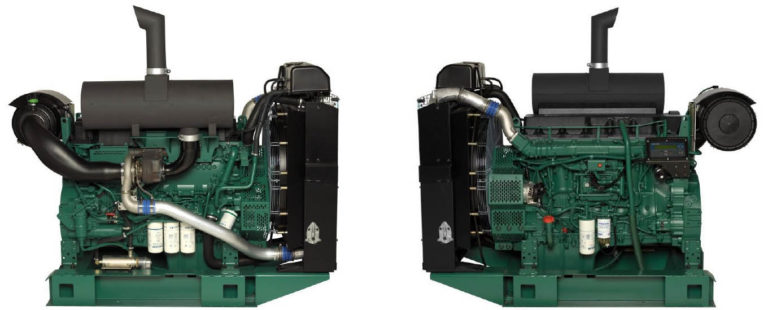

We Supply & Repair Volvo Penta TAD1345VE Engines

2.8 liter, in-line 6 cylinder

TAD1345VE is an off-road, in-line 6-cylinder, 12.8-liter diesel engine. It features electronic high-pressure injection, overhead camshaft, and turbo.

HIGH PERFORMANCE

High power and torque already at low engine speed. Well-balanced for smooth operation & low noise levels.

EASY SERVICE AND MAINTENANCE

Compact, simple installation and easy to service. Easily accessible service points. All service points are located on one side. Replaceable cylinder liners valve guides and valve seats.

FUEL EFFICIENT

High-tech injection system and highly efficient charge air system with low internal losses contributes to excellent combustion and low fuel consumption.

FEATURES

- High torque

- Highly efficient cooling system with Air to Air Intercooler

- High power density

- Fully electronic with EMS 2

- Complies with EU Stage II / EPA Tier 2 emissions

- Wide range of optional equipment including visco fan.

TECHNICAL DESCRIPTION

ENGINE AND BLOCK

- Cast iron cylinder block with optimum distribution of forces without the block being unnessarily heavy.

- Wet, replaceable cylinder liners

- Piston cooling for low piston temperature and reduced ring temperature

- Tapered connecting rods for increased piston lifetime

- Crankshaft has induction hardened bearing surfaces and fillets with seven bearings for moderate load on main and big-end bearings

- Case hardened and Nitrocarburized transmission gears for heavy duty operation

- Keystone top compression rings for long service life

- Viscous type crankshaft vibration dampers

- Replaceable valve guides and valve seats

- Overhead camshaft and four valves per cylinder

LUBRICATION SYSTEM

- Full flow oil cooler

- Full flow disposable spin-on oil filter

- The lubricating oil level can be measured during operation

- Gear type lubricating oil pump, gear driven by the transmission

- Oil level sensor at startup

FUEL SYSTEM

- Electronic high pressure unit injectors

- Fuel prefilter with water separator and waterin-fuel indicator / alarm

- Gear driven low-pressure fuel pump

- Fine fuel filter with manual feed pump and fuel pressure switch

COOLING SYSTEM

- Efficient cooling with accurate coolant control through a water distribution duct in the cylinder block. Reliable sleeve thermostat with minimum pressure drop

- Belt driven coolant pump with high degree of efficiency

- Electronically controlled viscous fan drive provides lower noise and fuel consumption (optional).

TURBO CHARGER

- Efficient and reliable turbo charger

- Electronically controlled Waste-gate

ELECTRICAL SYSTEM

- Engine Management System 2 (EMS 2), an electronically controlled processing system which optimizes engine performance. It also includes advanced facilities for diagnostics and fault tracing.

- Possibility to perform a start battery test according to the NCPA requirements via CAN bus signals.

- The instruments and controls connect to the engine via the CAN SAE J1939 interface, either through the Control Interface Unit (CIU) or the Digital Control Unit (DCU). The CIU converts the digital CAN bus signal to an anolog signal, making it possible to connect a variety of instruments. The DCU is a control panel with display, engine control, monitoring, alarm, parameter setting and diagnostic functions. The DCU also presents error codes.

- Sensors for oil pressure, oil temp, boost pressure, boost temp, coolant temp, water in fuel, fuel pressure and two speed sensors.