RELIABLE AND POWERFUL

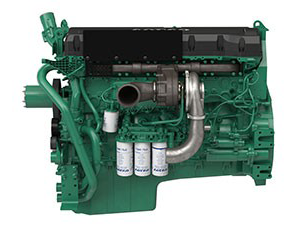

The TAD1662VE is a powerful, reliable and economical Versatile Diesel Engine built on the dependable Volvo in-line six concept.

LOW COST OF OWNERSHIP

World class fuel efficiency combined with a reliable engine aftertreatment system gives high uptime as well as low cost of ownership. No downtime for regeneration or decreased service intervals compared with current engine program.

COMPACT AND SIMPLE INSTALLATION

SCR technology selected by Volvo does not increase amount of cooling capacity needed. As optional equipment all material needed in order to install the engine can be ordered from Volvo Penta. Installation guidelines as well as drawings and CAD models are easy to access. The result is an engine and aftertreatment system that is easy to install with minor impact on existing machine layout.

DURABILITY & LOW NOISE

Long experince with SCR systems in combination with base engine development reduces risk of downtime. Well-balanced to produce smooth and vibration-free operation with low noise

POWER AND TORQUE

Maximum power and torque available at low rpm.

As a result noice as well as fuel consumption is very low. Useful engine speed for the TAD1662VE is due to power and torque layout very flexible.

LOW EXHAUST EMISSION

Efficient injection as well as robust engine design in combination with SCR technology contributes to excellent combustion and low fuel consumption. TAD1662VE complies with EU Stage 3b / EPA Tier 4i emissions.

EASY SERVICE & MAINTENANCE

Easily accessible service and maintenance points contribute to the ease of service of the engine.

As optional equipment possible to remote mount filters and service points.

FEATURES & BENEFITS

- Low cost of ownership and operation due to SCR technology

- Proven and straight-forward design

- Compact and simple installation

- High power and torque available at low engine speed

- Complies with EU Stage IIIb / EPA Tier 4i

- Wide range of optional equipment, please see order specification

- Engine and block

- Cast iron cylinder block

- Wet, replaceable cylinder liners

- Replaceable valve guides and valve seats

- Overhead camshaft and four valves per cylinder

- Full flow disposable spin-on oil filter, for extra high filtration

- Gear type lubricating oil pump, gear driven by the transmission

- Oil level sensor at startup

- Electronic high pressure unit injectors

- Fuel prefilter with water separator and waterin-fuel indicator / alarm

- Gear driven low-pressure fuel pump

- Fine fuel filter with manual feed pump and fuel pressure switch

- Available as Power pack or base engine.

- Belt driven coolant pump with high degree of efficiency

- Electronically controlled Waste-gate

- Engine Management System 2 (EMS 2), an electronically controlled processing system which optimizes engine performance.

- The instruments and controls connect to the engine via the CAN SAE J1939 interface. Options for engine control equipment.

- Emission levels compliance through SCR technology

- Several DEF tanks available as options

- Possibility to offer a wide range of installation material needed